Engineered Thermoplastic Resins Reduce Cost and Improve Performance Characteristics in Metal Replacement

Today's economy has forced many companies to put a larger emphasis on cost reduction while still upholding the same performance quality and standard.

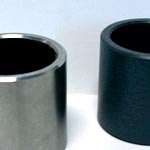

One solution in which many manufacturers are now incorporating is replacing metal and other traditional materials with engineered thermoplastics or high performance plastic resins.

This is a key strategy in the medical and dental industries, electronics, automotive, aerospace, and defense industries because of the following benefits:

Performance

- Engineered thermoplastics are lighter in weight, providing for ease of use and reduction in transportation cost for both parts and raw materials

- High performance resins provide resistance to corrosion, chemicals, and rust, reducing the need for secondary coatings and sprays

- Engineering resins can be non-conductive, improving safety for certain applications

- UV resistant properties provide longevity to products and also reduce need for secondary coatings and sprays

Sensory

- Noise and vibration dampening as compared to traditional metal parts

- Temperature stability (resistance to reaching extreme temperatures)

Processability / Manufacturing

- Ability to mold complex geometry and multiple parts reduce the amount of metal components and/or secondary operations and assembly

- A single plastic injection molded part can often replace multiple metal pieces, reducing the amount of fixtures and handling required to assemble those metal parts together

- Specific gravity of thermoplastic resins is much less than metal, reducing material required

- Increased speed to market due to shorter cycle and processing times

- Many thermoplastic materials can be recycled, reused, or reprocessed (plastic regrind), helping to further reduce waste and cost

Design / Appearance

- In-mold decoration or texturing helps reduces need for secondary operations

- Color options allow for resin to be colored prior to molding

Autronic Plastics, Inc. works very closely with the customer to fully understand the part functionality and requirements and collaborates on designing a part for manufacturability. API engineers partner with the customer through all stages of design, material selection, mold design, testing, processing, and production. API's expertise in converting metal components to plastic parts allow for our customers to reduce overall product cost and weight while improving performance.

Check out our engineering resin guide for examples of Metal Replacement Options.