ISO 9001:2015 Quality Systems

Quality Standards

"API doesn't follow industry standards, we set them." Quality standards are set higher every day with each product that is produced. Whether you need to meet UL, ISO, SAE, or another convention, API's level of excellence will exceed your quality expectations.

Autronic Plastic's quality system is based on three basic elements:

- ISO 9001:2015 quality standards

- Precise customer specification and delivery requirements

- API's core quality principles and beliefs

- Quality inspection guidelines are tailored to meet specific customer requirements

- Written inspection reports and client specifications are retained electronically

- All ISO documents have been written and approved by qualified department managers

API is a UL Certified Assembler and Molder

Quality Inspection Equipment:

- Brown and Sharpe MicroXcel PFx 454 touch probe CMM with PC-DMIS software

- Brown and Sharpe Microval Coordinate Measuring Machine with ROI CMM Video probe

- Computerized SPC System

- On-going destructive and non-destructive testing of parts

- Nikon Optical Comparitor

- Fully integrated Quality Assurance Manual (ISO QAM)

- Taguchi Design of Experiments

- State-of-the-art inspection and metrology equipment

- Various pins, gauges, and other measurement tools

API strives to achieve "Right the First Time" product launches – delivering the exact product promised, at the highest quality expected, in a timely, cost effective manner.

Autronic Plastics, Inc. has provided high quality and high precision plastic parts for over 60 years. We excel where other molders have failed and are always looking forward to our next challenge:

Please contact us to discuss your most complicated plastic designs, including:

- Complex geometries

- Difficult-to-process, exotic materials

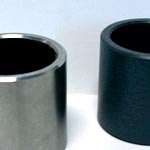

- Metal replacement applications

- Rubber replacement applications

- Tight tolerances